ZET - TechNology

Support in Steel Industry

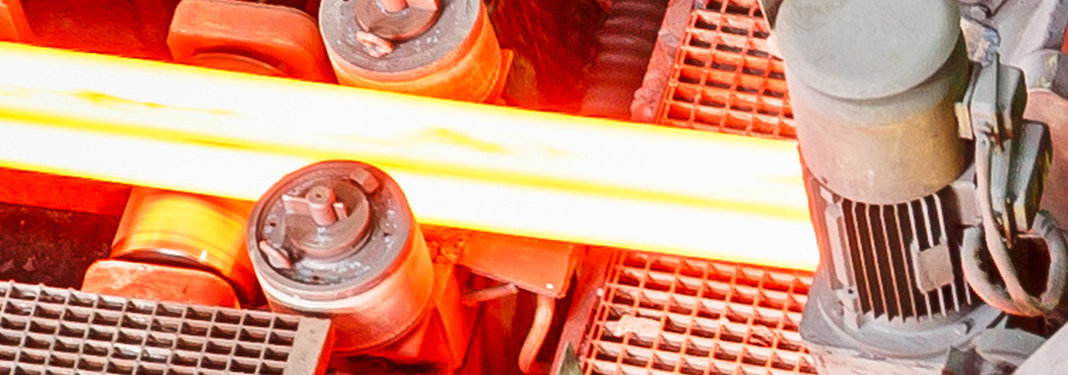

Rolling mill furnaces

Push and walking beam furnaces

We have many years of experience with rolling mill furnaces. These experiences relate to the optimization of existing furnaces as well as the engineering, installation and commissioning of new plants.

- Furnace new construction and repairs, design of the furnace zones, heat balance, preheating, heating and balancing zone (hearth area)

- Water-cooled support tube systems as well as refractory insulation (concrete parts and fiber materials)

- Heat exchangers and exhaust technology, improvement of the furnace efficiency

Refractory:

- New lining and lining repair of all oven areas

- Engineering of lining concepts

- Organization and execution of linings

- Furnace condition assessments of the individual areas

The lining of a wide variety of furnaces in classic brick settings insulation brick linings or fiber linings / ceramic fibers, organic fibers, "Lining and Cladding", zinc inducers with trickle or rammed masses are also part of our experience.

- Hot-dip galvanizing

- Forging

- Annealing furnaces

- Roasting furnaces (iron oxide)

- Laboratory furnaces

ZET-technology

Support in Steel Industry

8700 Leoben

Austria

email: office@zet-technology.com

www.zet-technology.com